Warm congratulations to a certain state-owned enterprise on the successful shipment of its heat exchanger units!

Warm congratulations to a certain state-owned enterprise on the successful shipment of its heat exchanger units!

This state-owned enterprise has evolved from a traditional power sector player to a global equipment manufacturing conglomerate. As a leading global brand, it has taken on the responsibility of being the backbone of China's intelligent manufacturing.

In 2022, the State Council issued a document, taking the lead in supporting the construction of pilot zones for green, low-carbon, and high-quality development in certain regions within China. As a leading brand in the equipment manufacturing industry, with multiple national-level green factories, we frequently take actions based on our industry-leading position, leading the industry towards green development.

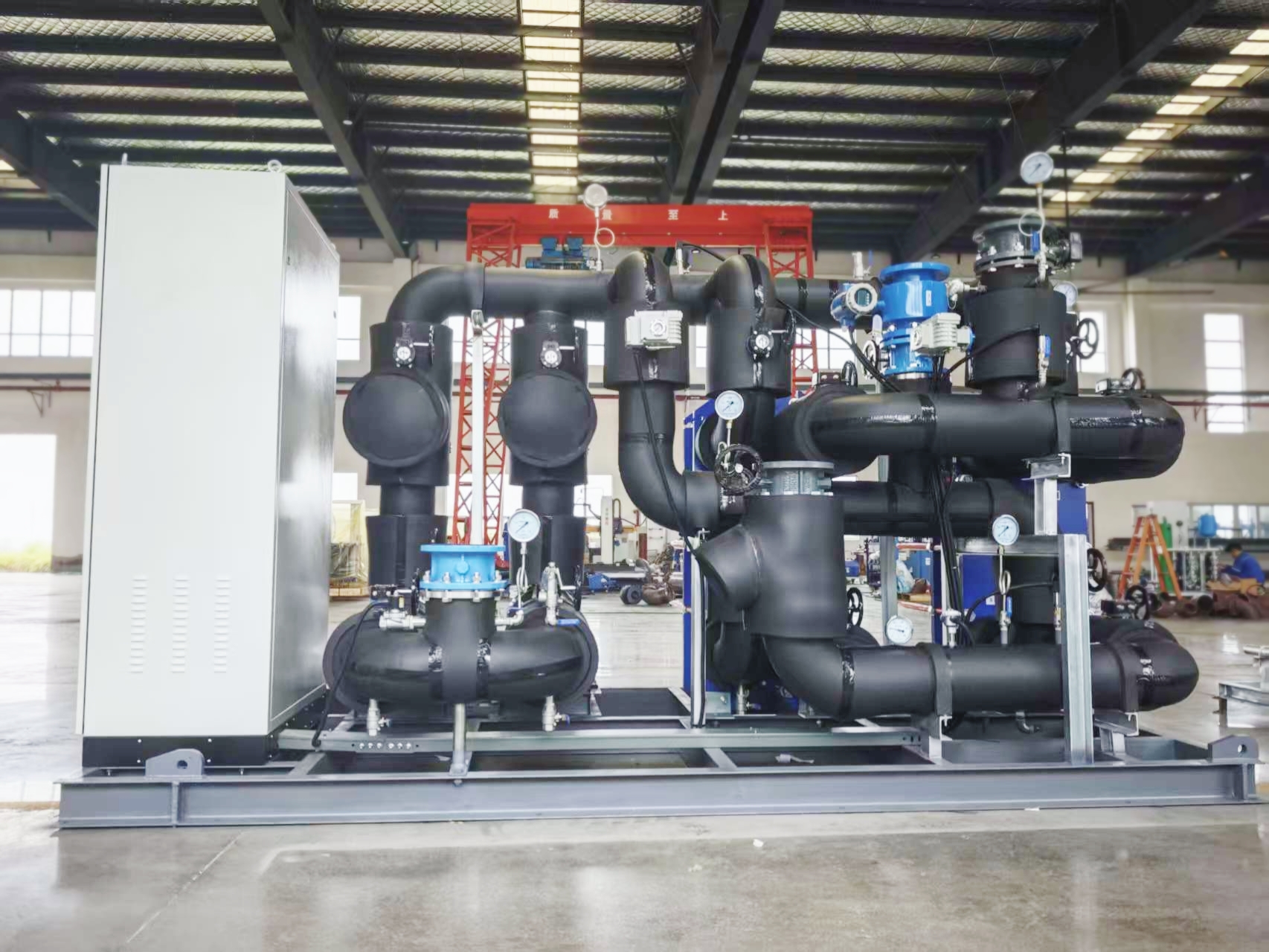

For the renovation project of the traditional factory area of this state-owned enterprise, Firstpower is customer-oriented, continuously optimizing its integration, and developing a technologically advanced overall solution. Focusing on the ideas of reducing energy consumption and enhancing competitiveness, the project mainly focuses on "system optimization", "waste heat recovery", "intelligent control", and "management improvement". We strive to research, develop, and produce the steam-water heat exchanger units required for the project!

For this project, the overall dimensions of the steam-water heat exchanger unit provided by Firstpower are: length * width * height = 3m * 2.3m * 2.1m. It features the following system characteristics:

(1) System optimization and integration: Implement modular variable frequency units and optimize pipeline design to achieve on-demand energy supply, reduce the phenomenon of "a big horse pulling a small cart", reduce transmission losses, and enhance steam dryness.

(2) Intelligent control and fine management: Establish a structured energy-saving process to achieve optimized operation throughout the entire process of management, maintenance, and operation.

(3) The equipment is compact in structure and easy to install.

The high-efficiency energy-saving retrofit of PCW units (Process Cooling Water) is an effective means for many enterprises to reduce production costs and enhance competitiveness. Yili Fluid focuses on "system optimization and equipment upgrading" as well as "intelligent control", providing integrated optimization of cold sources.

The dimensions of this PCW unit are: length * width * height = 3.95m * 1.95m * 2.15m. The main system features are as follows:

(1) System optimization: The adoption of high-efficiency plate heat exchangers, fully variable frequency water pumps, optimized pipeline design, and insulation measures collectively reduce the overall operating costs of the system.

(2) Intelligent control: Equipped with an intelligent control system, it coordinates and processes the primary side cold source, dosing, and pressure stabilization systems, achieving excellent control over system water temperature, pressure, water quality, and water pumps.

(3) Fine management: In addition to being controlled by an on-board intelligent machine, it can also be connected to the venue monitoring system to achieve predictive maintenance.

Firstpower has always been deeply engaged in the integration technology of cold and heat source systems, innovatively achieving efficient temperature control through products such as high-efficiency integrated cold stations, heat exchanger units, and PCW units, providing green and intelligent thermal energy and cooling solutions for industry.